Common industrial inkjet printing technology - CIJ, DOD

Date: 2024-07-11 Categories: Industry News Hits: 692

With the advent of digital inkjet technology, it has become a convenient and fast way to print at home. Although inkjet technology has been used for specialty printing since the 1950s, the impact of the technology in a wide range of industrial applications is only now becoming apparent.

Common inkjet technology for industrial printing

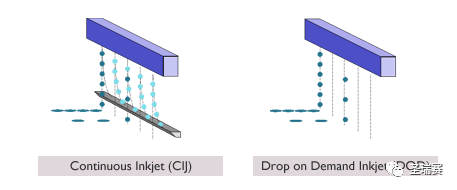

Industrial inkjet printing systems and the industrial inkjet printhead on which they are based are roughly divided into continuous inkjet (CIJ) and on-demand drop inkjet (DOD), with variations in each category, and on-demand drop inkjet (DOD), which in turn includes high resolution inkjet printing systems. As the name suggests, continuous inkjet (CIJ) is the continuous spraying of water droplets from the print head, which are then directed to the substrate as printed droplets, or to the collector for recycling and reuse. On-demand drop inkjet (DOD) is the ejection of water droplets from the print head only when needed.

Continuous inkjet (CIJ), on-demand drip inkjet (DOD)

1. Continuous Inkjet Printing (CIJ)

Continuous inkjet printing (CIJ) is primarily used for coding and marking products and packaging.

In this technology, a pump directs fluid from a reservoir to one or more small nozzles that use vibrating piezoelectric crystals to spray a continuous stream of droplets at high frequencies (about 50 kHz to 175 kHz). The droplet passes through a set of electrodes, transferring an electric charge to each droplet; The charged droplets then pass through a deflector plate, which uses an electrostatic field to select the droplets to be printed, collect them, and return them for reuse. For multistage CIJ, the printed droplets are deflected to multiple locations on the substrate, while for binary CIJ, undeflected droplets are printed.

CIJ's high drop injection frequency provides the capability for ultra-high-speed inkjet printing, suitable for applications such as date coding of beverage cans; Another advantage of CIJ is the high drop rate (about 50 m/s), which makes the distance between the print head and the substrate relatively large. Historically, CIJ has had an advantage over other inkjet technologies in using volatile solvent-based inks, allowing for rapid drying and helping to adhere to many substrates. Disadvantages of the technology include relatively low print resolution, very high maintenance requirements, and the perception that CIJ is a dirty and environmentally unfriendly technology due to the large amount of volatile solvent-based liquids used. In addition, the requirement that the print fluid be rechargeable limits the applicability of the technology.

2. On-demand drip inkjet printing (DOD)

On-demand drip (DOD) is a broad classification of inkjet printing technology. Typically, droplets are formed by a pressure pulse generated within the printhead and are only sprayed from the printhead when needed. The special method used to generate this pressure pulse creates its major subcategories, "thermal" and "piezoelectric", within DOD on-demand printing.

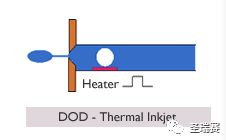

a. Thermal inkjet (TIJ)

Thermal inkjet technology (TIJ) is primarily used in home desktop printers, but has also made some progress in certain industrial inkjet applications.

In this technique, ink droplets are formed by rapidly heating a resistive element in a chamber containing ink. The temperature of the resistance element rises to 350-400ºC, causing a film of ink above the heater to evaporate into rapidly expanding bubbles, which creates a pressure pulse that forces ink droplets through the nozzle. The ejection of the droplets leaves a gap in the chamber, which is then filled by a replacement fluid in preparation for the formation of the next drop.

Advantages of thermal inkjet technology include very small droplet size and high nozzle density; High nozzle density results in compact devices, reduced print head costs, and the possibility of high native print resolution. The disadvantages of this technology are mainly related to the limitations of the available liquids; The fluid must not only contain an evaporable material (usually an aqueous solution or partial aqueous solution), but must also be able to withstand the effects of ultra-high temperatures; If the liquid is not designed properly, these high temperatures can cause a hard coating to form on the resistance element, reducing its efficiency and ultimately reducing the life of the print head; In addition, high temperatures may disrupt the function of the fluid (such as certain biological fluids and polymers) as a result of reaching high temperatures.

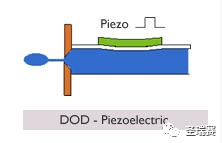

b. Piezoelectric ink jet

Piezoelectric (piezoelectric) drip inkjet technology is currently used in most existing and emerging industrial inkjet applications.

In this technique, the piezoelectric crystal (usually lead zirconate titanate) deforms when an electric field is applied; This deformation is used to create a pressure pulse in the ink chamber, which causes ink droplets to eject from the nozzle. There are many types of piezoelectric inkjet structures, including tubes, edges, faces, moving walls, and pistons, which use different configurations of piezoelectric crystals and nozzles.

The advantages of piezoelectric inkjet technology include the ability to spray a wide range of liquids in a highly controlled manner, as well as the good reliability and long life of the printhead. The main disadvantage is the relatively high cost of the print head, which limits the applicability of the technology in low-cost applications

MHJ-E series Handheld Fiber La...

MHJ-E series Handheld Fiber La...  UV. series. UV flying laser ma...

UV. series. UV flying laser ma...  MHJ-T series Handheld Fiber La...

MHJ-T series Handheld Fiber La...  G series CO2 flying laser inkj...

G series CO2 flying laser inkj...  MQ series UV laser marking ma...

MQ series UV laser marking ma...  4.3-inch screen printer

4.3-inch screen printer  10-inch screen printer

10-inch screen printer  7-inch screen printer

7-inch screen printer  5-inch screen printer

5-inch screen printer  Handheld inkjet printer suitab...

Handheld inkjet printer suitab...  Mini inkjet printer suitable f...

Mini inkjet printer suitable f...  Handheld inkjet printer suitab...

Handheld inkjet printer suitab...  Remanufacturing Hp 45SI quick-...

Remanufacturing Hp 45SI quick-...  Tij continuous ink supply syst...

Tij continuous ink supply syst...  TIJ IUT-300S Half an inch Sol...

TIJ IUT-300S Half an inch Sol...  TIJ IUT-300S Half an inch Sol...

TIJ IUT-300S Half an inch Sol...  Tij Ink Solvent ink Water-base...

Tij Ink Solvent ink Water-base...  Tij Water-based Black pigment ...

Tij Water-based Black pigment ...  Tij Water-based Black dye ink ...

Tij Water-based Black dye ink ...  Tij Water-based Black dye pigm...

Tij Water-based Black dye pigm...  Tij Water-based Black dye ink...

Tij Water-based Black dye ink...  Control System

Control System